Laser Engraving vs Marking vs Etching: What’s the Difference?

In today's age of custom manufacturing and personalised products, laser technology plays a crucial role in branding, decoration, and industrial processing. But if you're new to the world of lasers, the terms laser engraving, laser marking, and laser etching can be confusing.

Although often used interchangeably, each technique has distinct characteristics and applications. In this guide, we’ll break down the differences between laser engraving, marking, and etching — so you can choose the best method for your next project.

How Does a Laser Engraving Machine Work?

A laser engraving machine works by directing a focused beam of light through mirrors and lenses using computer-controlled motion. This beam follows a preset vector path, vaporising, melting, or altering the surface of the material to create precise markings.

The intensity, speed, and frequency of the beam can be customised to match different materials and desired effects — whether you need deep engravings, high-contrast marks, or subtle surface etching.

What Is Laser Marking?

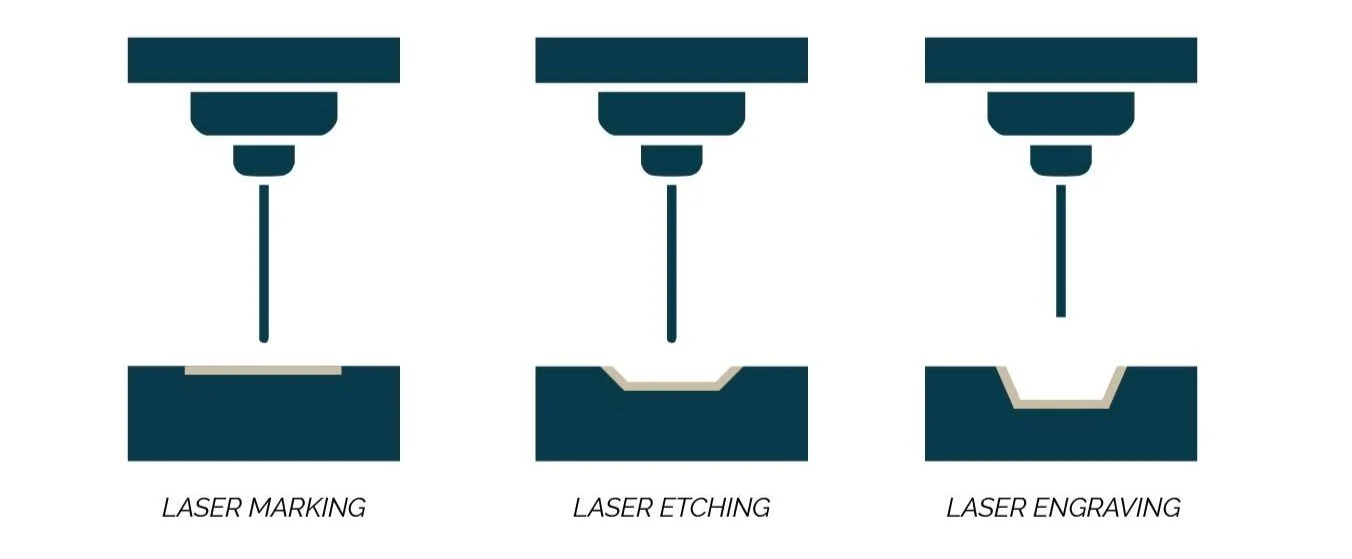

Laser marking is a noninvasive process in which a focused laser beam changes the surface colour of a material without cutting into it. The laser heats the material, creating a high-contrast, permanent mark—often in black, grey, or white tones.

Standard Laser Marking Methods:

Annealing (Metal Marking): Oxidises the surface of metals like stainless steel or titanium to produce a mark without material removal.

Carbonisation (Organic Materials): Burns or darkens materials like wood, leather, and paper for visible contrast.

Laser marking is ideal for:

Barcodes, serial numbers, logos

Medical instruments

Electronics and component identification

What Is Laser Engraving?

Laser engraving involves removing layers of material to create deep, precise engravings. Also known as laser ablation, this method vaporises the material using a high-powered laser beam, forming a cavity that reflects your design.

Key Features of Laser Engraving:

Creates depth by passing the laser over the same spot multiple times

Works well with metals, wood, acrylic, stone, and glass

Provides exceptional durability and detail

Laser engraving is perfect for:

Custom signs and business plaques

Personalised gifts like chopping boards and jewellery

Outdoor signage and industrial components

What Is Laser Etching?

Laser etching is a subcategory of engraving where the laser melts the surface of the material to form a shallow depression with raised edges. It’s commonly used for plastics and coated metals, offering quick, permanent markings without deep cutting.

Benefits of Laser Etching:

Faster than engraving due to lower material removal

Often used for plastic marking (e.g., foaming technique)

Produces high-contrast marks for logos and text

Ideal for:

Plastic parts and components

Consumer electronics

Light metal applications

Laser Marking vs Engraving vs Etching – Quick Comparison

Need Help Choosing the Right Laser Process?

At Laser Engraving Service, we specialise in laser engraving, marking, and etching services for a wide range of materials and industries. Whether you want to personalise a gift, label industrial equipment, or design a custom product, our experienced technicians can help bring your vision to life.

| Feature | Laser Marking | Laser Engraving | Laser Etching |

|---|---|---|---|

| Material Removal | ❌ No | ✅ Yes | ➖ Minimal |

| Marking Depth | Surface-level | Deep cavity | Shallow depression |

| Surface Texture | Flat, colour change | Indented, recessed | Raised edges, slight texture |

| Typical Materials | Metals, plastics, wood | Metal, wood, acrylic, stone | Plastics, coated metals |

| Speed | Fast | Moderate | Fast |

| Common Applications | Logos, serial numbers, barcodes | Signs, personalised gifts, plaques | Plastic parts, light metal marking |

📞 Contact us today to discuss your project and discover which laser process is right for your needs.